The Project

The PROBING project, co-financed under the P2020 programme promoted by the Portuguese Government and the European Commission, aimed at the creation and validation a new product for the detection of defects in welded joints obtained by laser brazing, using innovative inspection techniques and non-destructive testing (NDT). This product allow, for the first time, the automatic inspection of the quality of this type of joint with challenging geometry, right after the brazing process and in all parts processed on the assembly line, also contributing to the early identification of potential problems in the machinery. In this way, it is possible to reduce the high costs for the manufacturer when defects that compromise the structural capacity of the car and, consequently, the driver’s safety are detected late. The design of the system followed the standards adopted and driven by the concept of Industry 4.0.

Goals

The PROBING project is based on the following main objectives:

- To create new techniques for quality inspection of weld beads obtained from laser brazing, allowing full measurements in a reduced time;

- To create a device that allows the application of the techniques of weld bead inspection, even in riveted joints with complex geometry;

- To use the measurements of weld bead inspection to identify and report indications of potential failures in the process;

- To contribute to the improvement of production processes and waste reduction in the national industry;

- Expand the offer of products and services of the integrator company Introsys;

- Increase the competitiveness of current and future industrial customers of Introsys;

- Enhance technology transfer between academia and industry;

- Contribute to the dissemination of ICT in national industry;

- Contribute to the creation of specialised jobs in the region.

Consortium

The PROBING project counts with a consortium composed by 3 entities: Introsys, the consortium leader and a reference company in the creation of solutions for industrial automation; the Department of Mechanical and Industrial Engineering (DEMI) of the Faculty of Sciences and Technology of the NOVA University of Lisbon (FCT NOVA), which guarantees technological excellence in the development of the innovative solutions proposed in the project; and finally, Volkswagen Autoeuropa, which is the end user, the responsible for the requirement definition and host for the demonstration and validation of the results obtained throughout the project.

Project Activities

Overview, Requirements, and Specifications

This phase began with a study of the state-of-the-art related with quality inspection methods used in or adequate for welding processes for the manufacturing industry, followed by the definition of industrial requirements, use cases for the inspection processes, and design of the reference architecture, ending with the elaboration of the business model for the exploitation of the project results.

New miniaturized probes for inspection of brazed joints by laser

In this phase, the development process of the eddy currents and alternating current potential drop probes took place. During activity 2, the mechanical chassis that incorporates the different methodologies was designed and evaluated through integration, calibration, and testing in a simulated environment.

Software modules for applying the inspection system

The third task comprised all the software development proposed in the project, that is, processing and analysis of the signals collected from the probes, identification of defects, integration with the end- user management system, data analytics and preventive maintenance, and finally a graphical interface for the operator to interact with the developed system.

Integration, testing, and final validation of the system

This phase of the project focused essentially on the final integration and testing of the different modules developed in the previous phases. After its validation, the prototyped system was tested first in a controlled environment (TRL5) and later in an industrial relevant environment (TRL7).

Divulgation and dissemination

This activity was dedicated to the wide industrial and scientific dissemination, carried out through workshops, industrial fairs, scientific articles, and website.

Project Management

This activity centred the technical, administrative, and financial management of the project.

Results

The PROBING project ended in November 2021, highlighting the following proposed achievements:

- Development of a probe for quality control of geometrically complex welded joints obtained by laser brazing methods, offering real-time measurements;

- Development of a dedicated software to analyse the probe measurements in order to identify the presence of inner and superficial defects, with an integrated statistics module;

- Elaboration of the flyer with project goals (download here);

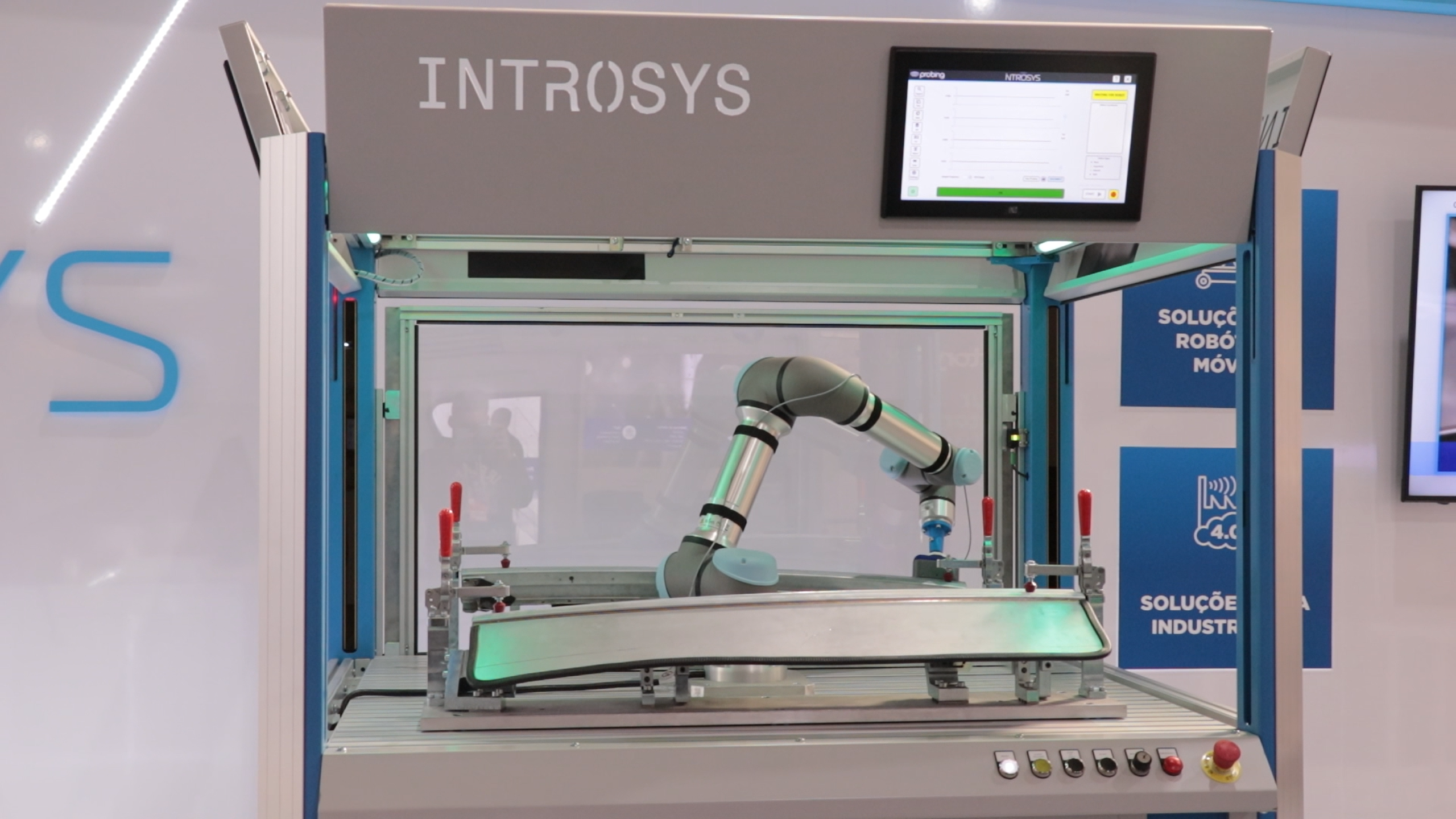

- Development of an inspection process demonstrator with a collaborative robot;

- Integration in an industrial environment in a test cell at Volkswagen Autoeuropa;

- Creation of 3 videos resulting from the tests and dissemination of the project (Video1, Video2 and Video3);

- Elaboration of the flyer with project goals and results (Download here);

- Publication of 2 articles (Article 1 and Article 2);

- Submission of a European patent – Nr 21211512.5.

Events

MOLDPLAS 2021

In November 2021, Introsys participated for the first time in the MOLDPLAS fair at the Expo Salão in Batalha, marking the first public presentation of the demonstrator developed under the Probing. During this event, on November 4, a workshop was held to present the project results to stakeholders and the general public. https://exposalao.pt/pt/feira/moldplas

EMAF 2021

On December 1-4, 2021, Introsys participated in EMAF, the largest Portuguese industrial fair. The Introsys stand included the demonstrator resulted from the Probing project, as well as other Introsys projects under development. https://emaf.exponor.pt/

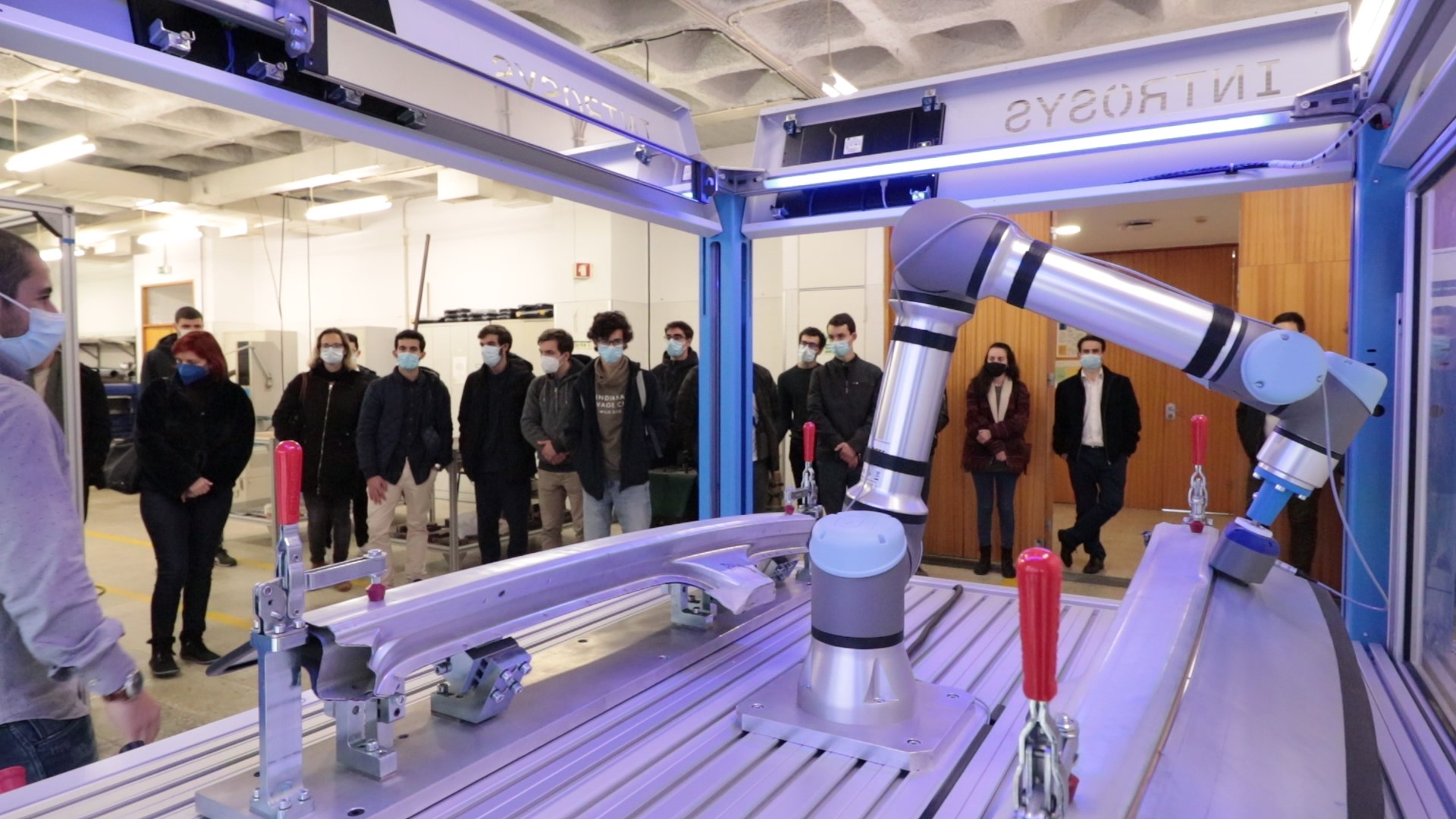

Workshop NOVA School of Science and Technology I FCT NOVA

In the scope of the dissemination activity of the Probing project, on November 24th, a workshop was held for the academic community at NOVA School of Science and Technology | FCT NOVA. It was a scientific event with focus in demonstrating the technology used in the scope of the project.

Contacts & Location

Address

Estrada dos 4 Castelos Lote 67

2950-805 Quinta do Anjo, Portugal

Castelo Branco Delegation

CEI – Centro de Empresas Inovadoras, Salas S2.05 e S0.02

Av. do Empresário 1,

6000-767 Castelo Branco, Portugal

GPS: N 39°48’51.8 W 7°30’24.1

Contacts

+351 212 951 499

Call to national fixed network